The Two Towers: The Caissons

Previous posts in the New Narrows Bridge Series:

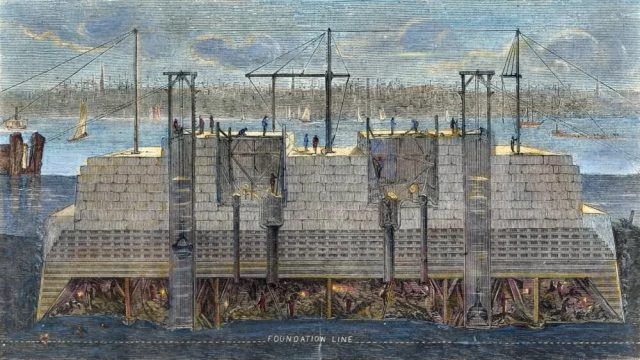

The Bridge Foundations: The Caissons

The Caissons

The Narrows Bridge caissons, the foundations for the towers, underwent initial construction in the Port of Tacoma, and were towed to their location in the Narrows, where they were secured in place on the surface with a series of anchor cables arranged radially. These radial cables and flotation tanks in the caissons, were used to control the position and descent of these floating concrete islands, as layers of concrete were added to the top. A sharp cutting edge was built into the bottom, to ensure the caissons would reach bedrock to ensure stability when the weight of the towers was added.

The task was akin to building a 25-story building from the roof down, all the while holding its precise position in the alternating rip tides of the Narrows. The bottom of the caissons is configured to be a mammoth cookie cutter, with a sharp steel knife edge to cut through sediments to reach bedrock 50 feet beneath the bottom.

The process proceeds as follows: the caisson cutting edge fabricated in the Port is towed by tugboat to the site and secured to radial anchors positioned by GPS. Flotation chambers – steel drums filled with compressed air – are used to control the buoyancy.

Concrete is poured into steel forms built inside the perimeter of the box. The caisson becomes heavier and sinks into the water, the position controlled by its radial guides. Dredge well tubes are used to evacuate the loose surface soil once the bottom is reached until the caisson sinks to its predetermined depth on bedrock.

One fascinating story about this process. A diver was cutting away the flotation barrels when his arm was grabbed and the torch torn away – by a Giant Pacific octopus! He grabbed the torch back – only to have it wrestled away again by the octopus. He then radioed to the surface: “I think I’ve done all can today, it’s time to come back up.”

Amazing, intelligent, curious creatures these octopi…